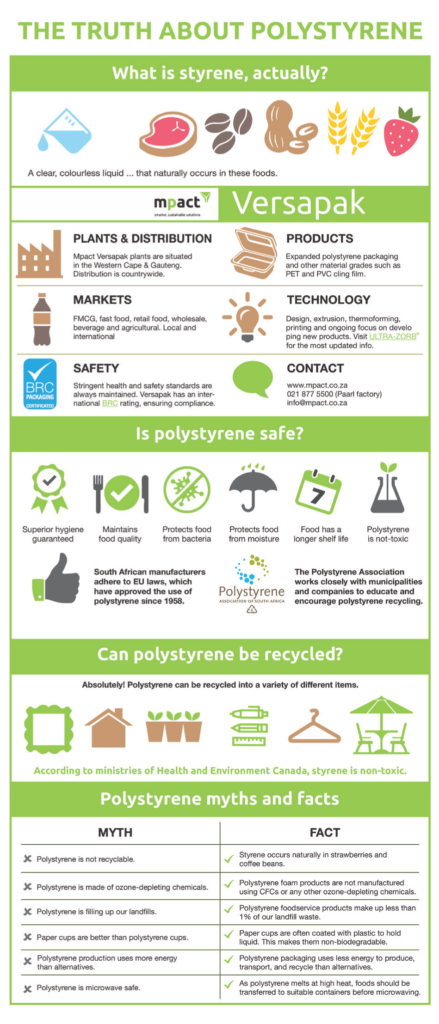

In the previous edition, Mpact Versapak explored packaging additives that assist with beverage preservation. This month we consider the safety of packaging that is in direct contact with the food we consume. With Vinyl (Polyvinyl Chloride) and Polystyrene regularly under the spotlight, let’s iron out some misperceptions and understand which accreditations and certifications to look out for in order to safely package our food. Items produced from Vinyl* and Polystyrene materials typically include cling wrap, which is used in retail, bakery, and take-aways.

Packaging suppliers can reassure the market of their food safety commitment by displaying their compliance to the BRC or FSSC standards and good manufacturing practices. BRC and FSSC standards are internationally recognised. These certifications ensure that the packaging meets or exceeds food safety requirements. Under the BRC certification, an organisation, such as Mpact Versapak, commits itself to being regulated to only use raw materials that are safe for direct food contact. The raw materials used in the packaging items should be certified for this type of use and should conform to European Food Safety Standards, EU directive 10/2011 and/or FDA standards. Furthermore, a reputable organisation should also conform to Regulation EC No 1935/2004 on good manufacturing practices for material that come into direct contact with food, as well as the FSSC 22000 certification. These standards are encompassing and ensure that requirements for food packaging are met, as recognised by an array of stakeholders in the global food and food packaging.

When purchasing Vinyl or Polystyrene packaging items, one should enquire with the supplier regarding the compliance of the products. Certificates, based on annual audits, should be readily available and easily supplied. By making responsible purchases and complying with industry standards, various stakeholders along the value chain can make a responsible and legal contribution to consumer safety.