With hygiene in the spotlight, why is plastic packaging the preferred medium within the retail and home environments?

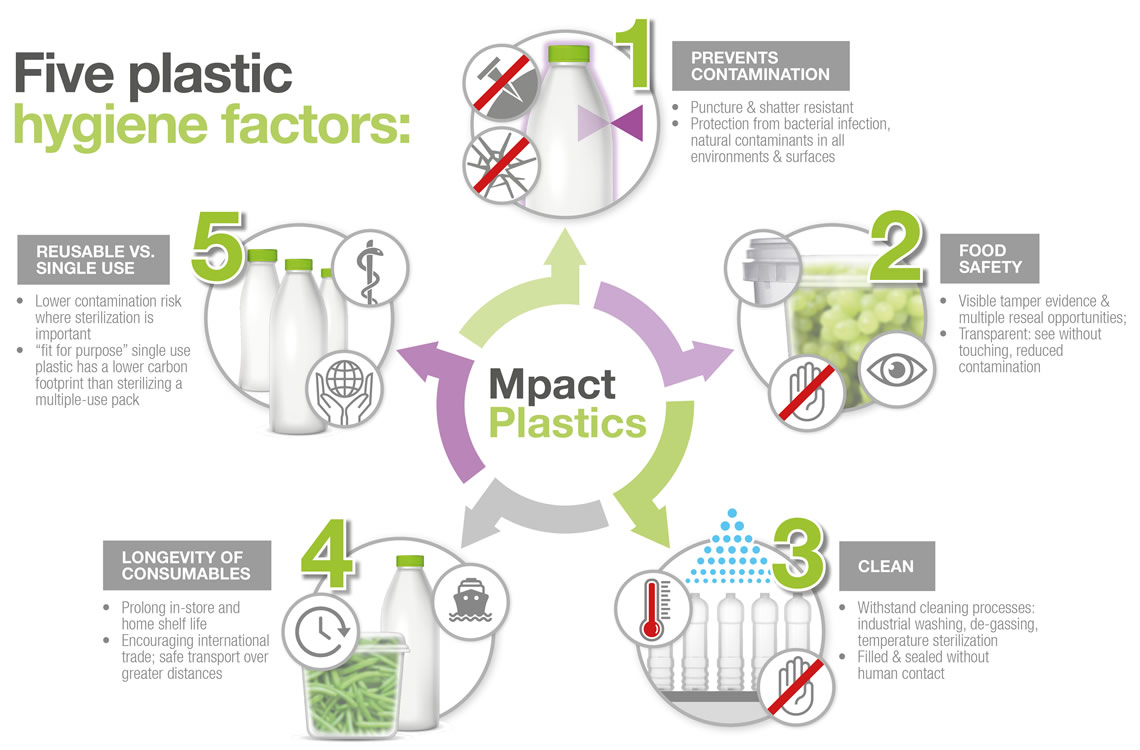

Due to its puncture and shatter resistant properties, plastic has the ability to reduce breakages and thereby lower the risk of contamination within the retail and home spaces, and surrounding work surfaces, whilst also protecting the contents from moisture, humidity, gasses and foreign bodies, including microorganisms.

From a food safety perspective, tamper evident designs that offer multiple reseal and child proofing opportunities keep the content protected, whilst enhancing consumer confidence. Transparent packaging also allows consumers to look at, but not touch consumable products, reducing contamination and bruising.

Plastic is a clean packaging medium as it can be filled and sealed, within many factories, without human contact. Most plastic grades can also withstand multiple industrial washing, de-gassing and temperature sterilization cleaning processes.

By extending the shelf life of most foods and produce throughout the distribution chain, plastic packaging lowers the carbon footprint, since food waste itself has a significantly higher carbon footprint impact, even compared to single use plastic items. Extended shelf life also encourages transport over longer distances and positively contributes by encouraging international trade.

Although the re-use of plastic packaging items are encouraged, certain single use items, for example, where sterilization is of importance, does provide benefits such as a lower contamination risk and preserving resources typically required by washing processes, making a fit-for-purpose single use item enjoy a lower carbon footprint than its multiple use alternative.

Mpact is the largest paper and plastics packaging and recycling business in Southern Africa with customers that include packaging converters, fruit producers, FMCG companies and other consumer and industrial packaging companies. Mpact’s integrated business model is uniquely focussed on closing the loop in plastic and paper packaging through recycling and beneficiation of recyclables. Mpact has 43 operating sites, 21 of which are manufacturing operations, located in South Africa, Namibia and Mozambique. Sales in South Africa accounted for approximately 87% of Mpact’s total revenue for the current period, while the balance was predominantly to customers in the rest of Africa. Mpact Operations (Pty) Ltd, the major subsidiary of the Group is a B-BBEE Level 1 contributor.

Mpact │011 994 5500 │ www.mpact.co.za│ info@mpact.co.za