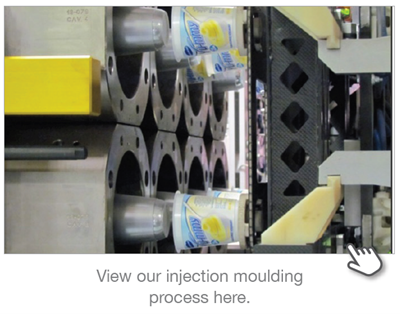

If a factory tour is more than a hop, skip and jump away, let’s walk virtually.

One of the key engagement opportunities with our customers is welcoming you to our manufacturing plants. Learning together creates opportunities for us to increase our understanding of your businesses and be forthcoming with great ideas that aligns with your business objectives, both commercially and from a packaging design perspective. This allows us to critically understand your brand and deploy our design service to create value beyond your imagination! By visiting our factories, we can help you understand how we create this benefit for you.

Let’s meet up, book your factory visit here!

We understand the pressures of your work life and aim to make our get-together as easy as possible. We’ve removed the stumbling blocks by also gearing ourselves to meet and ‘show you around’, online. Let’s start by explaining how we do what we do.

Across our plants, situated in Pinetown, KwaZulu-Natal, Atlantis, Western Cape and Wadeville, Gauteng, we focus on injection moulding of preforms, bottles and jars; single and two-stage injection stretch blow moulding of PET bottles and jars; extrusion blow moulding; and single stage moulding of both bottles and wide-mouth jars. We also manufacture a large selection of matching closures through compression and injection moulding and offer decorating options including in-mould labelling for tubs and jars, self-adhesive labelling for tubs & containers, screen and pad printing, shrink sleeving and closure wad insertion, slitting and folding.

Interaction between our FMCG and Wadeville sites enables us to offer an in-house service for both containers and closures, so that quality and cost efficiency can be optimised. Geographical diversity provides nationwide market access, effective customer response, lower transport costs and the advantage of regional manufacturing.

We would like to welcome you to any of our factories.

To book your team’s visit, please contact us here.